Dog food machine can be used for the production all kinds of dog foods, we will design the moulds to make different shapes according to customers'specific requirement on the shapes of their aimed products.

We have two types of dog food extruder, dry type and wet type, through feeding materials, extruding,cutting, drying, oil spraying, packing , the finished products are done once time fully automatically. The production line has following features: many models, flexible equipment configuration, wide range of raw materials, a wide variety of final products, and simple operation, can greatly improve the production efficiency and quality of fish feed, promote the growth of fish, and is the best choice for dog food production industry.

Flow chart of dog food production line:

Milling Machine→Mixer → Conveyor→ Extruder→ Conveyor→ Dryer→ Conveyor→ Flavoring machine→ Cooling Machine→ lifter Packing Machine

Application: With strong R&D capabilities, our engineers can provide tailored solutions based on customer requirements, plant size, and local conditions.

Investment. This dog food production line can be used to produce dog food, cat food, floating fish feed, animal feed, and more.

With the addition of a twin-screw extruder's die or die, shapes and sizes become increasingly diverse.

Dog food samples:

1. Raw Material Mixing: Corn, flour, rice, and other raw materials are mixed uniformly in a powder mixer.

2. Extrusion: A twin-screw extruder uses high-temperature extrusion to expand the dough and form it into a specific shape.

3. Filling Injection: A dedicated filling machine is used to inject fillings such as chocolate and syrup into the expanded dough to create a sandwich structure.

4. Forming and Cutting: A forming and cutting machine cuts the product into round and square bars.

5. Baking and Seasoning: The product is baked in a multi-layer continuous oven and seasoned with oil/sugar sprayers.

6. Cooling and Packaging: After automatic cooling, the product is sealed and packaged to complete the product.

| Size for whole line |

According to land size and layout. |

| Pellet size |

1-12mm |

| Capacity |

5-10t/h |

| Workers requirments |

4-5people |

| Shipment requirments |

5*40ft container |

| Range of application |

large commerical Aquatic/ pets feed factory |

| Process flow |

1.bucket elevator 2.raw materials cleaning system-3.silos for crusher 4.crusher 5.Raw material automatic distribution weighing system 6.mixing system 7.second crushing system 8.Raw material automatic distribution weighing system 9.second mixing system 10.extruder 11.drying system 12.screen system -13.seasoning machine 14.cooling system 15.packing system |

Features:

1. Various sizes of dog food pellet molds accommodate pets of different sizes.

2. Adjustable dog food pellet length to suit different feeding preferences.

3. Fast pelleting speed and efficient production.

4. High-quality ingredients for healthy and nutritious pet food.

5. Easy-to-use design for simple operation.

6. Sturdy and durable construction for a long service life.

Applications:

1. Industrial Production: The dog food pellet machine has different production lines to meet different production needs. The produced pet food can be marketed.

2. Home Use: Pet owners can use the dog food pellet machine to make healthy and nutritious food for their furry friends at home.

3. Pet Stores: Pet stores and animal shelters can use the pellet machine to make high-quality dog food for sale or adoption.

4. Farms: Farmers can use the pellet machine to make food for working dogs or to supplement the diets of livestock.

5. Zoos: Zoos can use the pellet machine to make specialized feed for the animals in their care.

Our Services

Pre-sales Service:

1. Free equipment consultation.

2. Standard equipment and flow charts provided.

3. We offer reasonable solutions and free design based on specific customer requirements, helping with equipment selection.

Post-sales Service:

1. Assist customers with factory design and provide professional advice, including free factory layout drawings.

2. Welcome to visit our factory.

3. Pre-shipment inspection of machines.

After-sales Service:

1. Overseas installation and commissioning.

2. Training for frontline operators.

3. Provision of basic formulas.

4. Operation/Service/Maintenance Manuals: Available in English.

For more information on process design, equipment layout, plant construction plan, single machine equipment quotation, turnkey quotation, etc., please feel free to contact us.

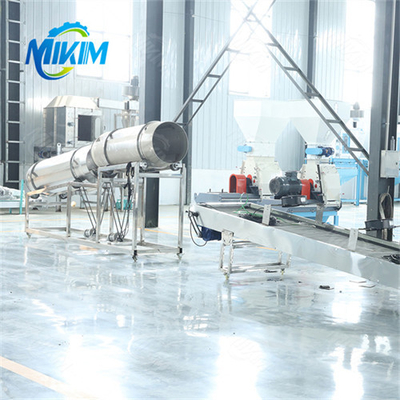

Equipment Photos

Qualifications and Honors

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!