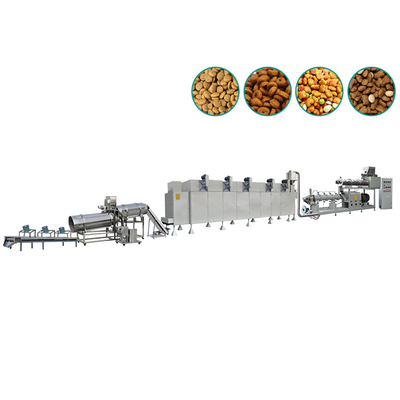

Pet Dog Feed Cat Food Poultry Feed Mill Pellet Pet Feed Production Line

Pet feed production line is used to make dog food, cat food and other pet food with different taste and shapes.Different shapes of pet food can be made through changing the dies.

The double-screw extruder consists of feeding system, extruding system, cutting system, heating system, transmission system and controlling system. We will feed the material from the feeding machine and get the tissue state by inflating the material and the machine barrel must be high temperature, high pressure and high cutting.

| Model |

NL85-II |

NL90-II |

NL130-II |

| Input Voltage |

380V 50Hz |

380V 50Hz |

380V 50Hz |

| Installed Power |

95kw |

145kw |

125kw |

| Power Consumption |

60kw |

85kw |

90kw |

| Production Capacity |

500-800kg/h |

800-1200kg/h |

1500-2000kg/h |

| Overall Dimension |

26000×1200×2300mm |

28000×1300×2500mm |

32000×1500×2800mm |

Technical Features of Floating Fish Feed Extruder

1. This extruder equipment adopts the auto-controlling speed feeding tool to produce the feed material evenly.

2. Electric heating device is adopted which can improve the feed expansion rate and pellets floating time.

3. High temperature and high pressure cooking process can kill the salmonellosis and bacterial infections and also makes the pellets easily to digest.

4. The cutting knife adopts the frequency controlling speed in order to change the material size.

5. The floating time can be controlled by the puffing degree adjustment.

6. Auto-temperature control system makes the temperature controlling more direct viewing and the parameter more precise.

Equipment list in the pet feed production line:

mixer→screw conveyor→twin screw extruder→air conveyor→dryer→hoister→flavoring drum and oil sprayer→cooling machine→packing machine

Blender Mixer

Blend Mixer is a high standard two-way ribbon mixing machine. It includes material tank, screw mixing paddles and drive parts.Screw mixing paddles are the double deck structure or three-tier structure. Outside of the screw paddles collecting and mixing the raw

materials flour from two borders area to the center area. Meanwhile, the inside of the screw mixing paddles conveying and mixing the flour materials from center to the borders. Then it makes the convective mixing to ensure the flour materials mixing evenly with high efficiency.

Double screw extruder

Double Screw Extruder Unit is the high standard and professional extrusion machinery unit. It’s consist of bucket elevator, Storage Silo, material conveyor, conditioner, feeder,extruder, electric controller and operation platform. The extruder includes drive system, extrusion system, cutting system,heating system, lubricating system and extraction steam system. Conditioner is designed as the advanced technology biaxial differential modulator. It can higher the materials temperature,make flour materials softer, lower the materials’ friction . Thus reducing the extrusion power consumption, increasing the

output, improving the stability of the extruder operation, prolonging life of t the whole extruder unit.

Hot Air criculation Baking oven

Heat With Infrared Ray Heating Tube, Raise And Lower Down Temperature Quickly, Small Heat Inertia And High Heat Efficiency.

Adjustable Transit Speed Of Net Belt With Accurate Temperature Control Device. Sliding Board Bottom Of Dryer For Easy Cleaning. Hot Wind Cycle Device Makes Heating Energy Equally In The Dryer

Double-Roller Chain And Chain Drive Make Stable And Smooth Running.

Single drum flavoring line

It’s consist of hoistor, drum machine, flavoring machine and oil sprayer.

The oil sprayer sprinkle the atomized oil to the products in the drum.By continuous rolling material, the drum will make oil and seasoner evenly adhere to the surface of products. To prevent feed leakage, the hoister is used wavy baffle belt.The oil sprayer can bear high temperature and pressure. Safe and durable. Mixing atomized oil and

products evenly in the flavoring drum.

Inverter to adjust the speed of spices. Easy to control.

Our screw extrusion technique has been widely applied to produce the following products:

1-Extursion floating and sinking fish feed, pet food ,

2-Pasta macaroni,

3-leisure snacks food ,

4-breakfast cereal food and corn flakes,

5-fried flour food, bread crumb,

6-textured soya protein and vegetarian meat, etc.

More than twenty production line can be chosen. And we can also provide customized service for special requirements.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!