The wood pellets can be made from many different materials,

such as wood and wood related, sawdust, rice husk, sunflower stalk,hulls, forestry wastes ...

More information about Wood Pellet Machine Wood Pellets Machine straw pellet prodution line

(1)Big Gear Box

The gearbox adopts big 3 level drive, with its module increased , gear strengths increased,carrying more and more ability.The service life has been increased 8-10 times than the traditional reducer, so it greatly increase the service life.

(2) Casting material of gearbox with high stability. Gearbox body is casted. Its features strong, good heat dissipation,low heat deformation, high steady etc. In the meanwhile it also avoid disadvantages such as bad sealing for welding boby, easily deformation due to high heat,low steady in basis.

(3) Siemens Brand Motor: This kind of motor is frequency and has thick copper coil, it won't be burned due to instantaneous current.

(4) Parallel vertical installation reduce energy consumption loss. The motor and main shaft of wood pellet machine supplier are parallel vertical installed , which can reduce energy consumption loss in the process of transmission, more output power, higher transformation of energy efficiency.

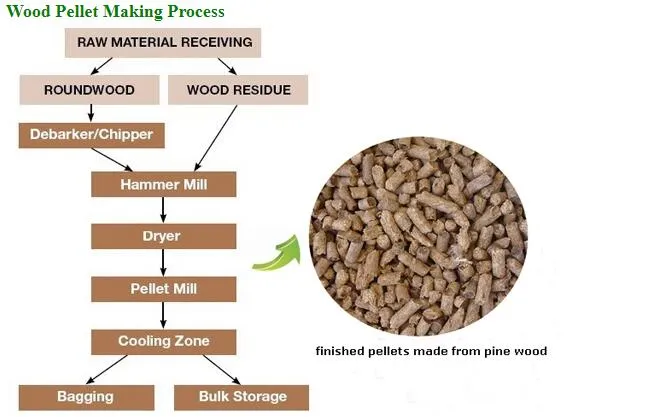

Process:

The material handling system primarily encompasses material storage, supply, and pretreatment.

Waste biomass raw materials must first be stored to ensure a continuous supply for subsequent production.

The raw materials are then pulverized and cleaned to remove impurities and meet pellet production requirements.

The pellet production system is the core component of the biomass fuel pellet production line.

In this process, the pretreated raw materials are fed into the pellet machine for compaction.

The pellet machine uses high pressure and appropriate temperatures to form the raw materials into pellets, adding a certain amount of binder during the process to ensure pellet strength.

The compacted pellets contain a certain amount of moisture and require dehydration in a drying system.

The drying system typically uses heat transfer to expose the pellets to high-temperature airflow, gradually reducing their moisture content and achieving the desired drying effect.

The dried pellets are then cooled in a cooling system.

Finally, the cooled pellets are fed into the packaging system for packaging.

| Model |

Power |

Mold Hole |

Capacity for industrial solid |

Capacity for biomass |

Pellet size(mm) |

| MK-36 |

45kw |

36 |

0.5-1.0 |

1.0-1.5 |

32*32*50-100 |

| MK-48 |

75kw |

48 |

1.0-1.5 |

1.5-2.5 |

32*32*50-100 |

| MK-72 |

110kw |

72 |

2.0-2.5 |

2.5-3.5 |

32*32*50-100 |

| MK-90 |

132kw |

90 |

2.0-2.5 |

3.5-5.0 |

32*32*50-100 |

| MK-120 |

200kw |

120 |

3.0-4.0 |

4.0-6.0 |

32*32*50-100 |

| MK-150 |

250kw |

150 |

4.0-6.0 |

6.0-10.0 |

32*32*50-100 |

The biomass fuel pellet production line is a complete set of equipment, including a material handling system, pellet production system, drying system, cooling system, and packaging system.

Through the coordinated operation of each link, this production line processes waste biomass raw materials into high-quality fuel pellets.

Finished product display

The production process of biomass fuel pellets undergoes multiple steps to ensure consistent product quality. Different packaging sizes can be customized to meet your needs, providing a wide range of options.

With the increasing demand for sustainable energy, biomass fuel pellet production lines are expected to see wider application in the future.

For more information on process design, equipment layout, plant construction plans, single machine equipment quotas, turnkey quotas, etc., please feel free to contact us.

Equipment Photos

Qualifications and Honors

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!