Straw Fuel Pellet Production Line

Product Specifications

| Attribute |

Value |

| Application |

Woodworking Industry |

| Blade Material |

Alloy Steel |

| Color |

As customer requirements |

Product Description

The biomass pellet fuel production line uses agricultural and forestry waste, such as wood chips, straw, rice husks, bark, sawdust, wood, branches, and tree trunks, as raw materials. After pretreatment and processing, it solidifies into high-density pellet fuel, making it an ideal alternative to coal and oil, saving energy and reducing emissions.

Raw Materials: Sawdust, rice husks, peanut shells, mushroom residue, etc.

Applications: Sawdust, rice husks, fruit shells, peanut shells, coffee husks, etc.

Target Customers: Agricultural supply companies, large furniture factories, wood processing plants, rice mills, oil refineries, and other users with advantageous raw material resources.

Fish food pellet production line

Technical Specifications

| Model |

Capacity |

Power |

Particle Size |

Product Size |

Weight |

| MK560 |

1-1.5T/H |

90KW |

4-12MM |

2620*1640*1770MM |

5.2T |

| MK560A |

1.5-2T/H |

132KW |

4-12MM |

2680*1560*1770MM |

5.6T |

| MK700 |

2-2.5T/H |

160KW |

4-12MM |

2560*1380*2020MM |

7.2T |

| MK860A |

3-4T/H |

250KW |

4-12MM |

3150*1550*2240MM |

9.5T |

How to make pellet

1. Use Wood Chipper, Wood Crusher to make wood logs, chips (or other materials) smaller.

2. Use Dryer (rotary drum dryer / Air-flow dryer) or add water to the sawdust(or other materials) till its moisture content between 8-15%, which is the best moisture content for pelletizing.

3. Put the sawdust into the pellet machine gradually. Large scale pellet production need a screw feeder to make sure stable feeding of raw material.

4. After pelletized, the pellets are of high temperature that is not suitable for direct packing. So they should be cooled by pellet cooler.

Then, pellets go through a vibrating sieve, where good pellets will be left, while broken ones or powder will be collected for reproduction.

5. After all the above procedures, pellets can be packed with a pellet packing machine.

Finished Product Display

Finished product display

Key Advantages

- Converts biomass raw materials into high-density pellet fuel, reducing environmental pollution

- Processes various biomass raw materials (straw, rice husk, wood waste) with strong adaptability

- Pellet fuel resists moisture and mold during storage, ensuring quality

- Produces fuels meeting different specifications through adjustable parameters

- Advanced control system for easy operation and management

- Environmentally friendly, economical, efficient, and sustainable solution

For more information on process design, equipment layout, plant construction plan, single machine equipment quotation, turnkey quotation, etc., please feel free to contact us.

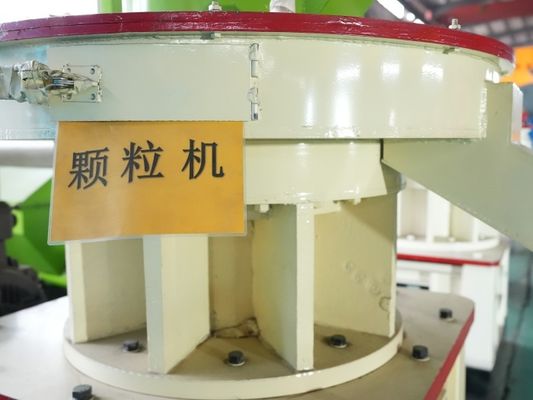

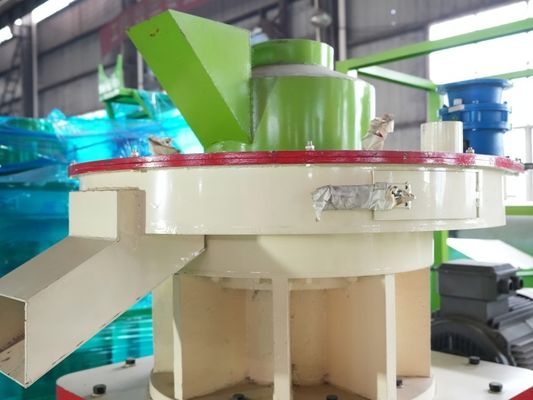

Equipment Photos

Equipment photos

Certificate of Honor

Certificate of Honor

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!