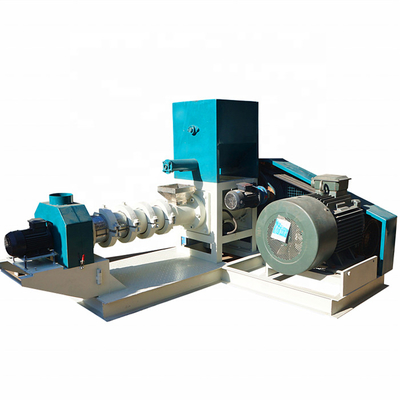

Complete Set Floating Fish Feed Extruder Machine Pet Feed Production Line Pellet Making Machine

Complete set floating fish feed extruder machine is widely used for producing grains into high-grade aquatic feed pellets for fish, catfish, shrimps, crab etc. The puffing pellets can float on water surface for over 12 hours,.According to your capacity and material ,We will suggest you different model floating fish feed machine.

Product Parameters

| Model |

Capacity |

Main power |

Feed power |

Screw dia |

Cut power |

Pellet size |

| DGP-40 |

40-60kg/h |

7.5kw |

0.4kw |

Φ40mm |

0.4kw |

1-12mm |

| DGP-50 |

60-80kg/h |

11kw |

0.4kw |

Φ50mm |

0.4kw |

1-12mm |

| DGP-60 |

100-150kg/h |

15kw |

0.4kw |

φ60mm |

0.4kw |

1-12mm |

| DGP-70 |

180-250kg/h |

18.5kw |

0.4kw |

φ70mm |

0.4kw |

1-12mm |

| DGP-80 |

300-350kg/h |

22kw |

0.4kw |

φ80mm |

0.6kw |

1-12mm |

| DGP-100 |

400-450kg/h |

37kw |

1.1kw |

Φ100mm |

0.6kw |

1-12mm |

| DGP-120 |

500-700kg/h |

55kw |

1.1kw |

φ120mm |

1.5kw |

1-12mm |

| DGP-135 |

800-1000kg/h |

75kw |

1.1kw |

φ133mm |

2.2kw |

1-12mm |

| DGP-160 |

1200-1500kg/h |

90kw |

1.5kw |

φ155mm |

2.2kw |

1-12mm |

| DGP-200 |

1800-2000kg/h |

132kw |

1.5kw |

φ195mm |

3.0kw |

1-12mm |

Raw materials: Wheat meal, maize powder, soybean meal, cottonseed meal, fish meal, bone meal, corn meal, meat meal, etc.

Moisture of raw material:20%-25%

Oil content: ≤10%

Starch content: ≥30%

Raw material type: powder

Final Products: Fish feed, dog food, shrimp feed, frog feed, poultry feed, fox feed, textured soybean protein, etc.

Twin Screw Extruder

To extrude the raw materials and make them to the required shape and size of the pet food fish feed pellets by mould.

They extruder grain powder into pet food by high temperature and pressure.The Twin-screw extruder is made of the feeding system, extruding system, cutting system, heating system, transmission system and controlling system.

1. The screws are made of the alloy steel and special craft, durable usage, high pressure, the screw life is longer.

2. Adopting the building block structure and combining willingly according to the different demand.

3. The forced lubrication system, so that it can guarantee the equipment transmission life longer 4. Auto-temperature control system; make the temperature controlling more direct viewing and the parameter more precise.

4. Self-cleaning, when stopping, it can be cleaned without disassembling.

THE REASONS WHY YOU CHOOSE OUR COMPANY

ONE: Pursue the highest level of Feed Processing Machinery in China,encourage customer to inspect machines by caliper and calculator. Select Siemens Motor,Choose Swedish SKF Bearing.

TWO: Transform factory into university,build the most professional training & trusteeship team in Chinese feed industry,Ensuring that machinery can be running in a healthy condition by remote supervisory control and nanny trusteeship service.

THREE: Material thickness of main equipment is more than feed machinery standard 2mm,you can weigh and contrast -- Please pick up the caliper and calculator to inspect.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!