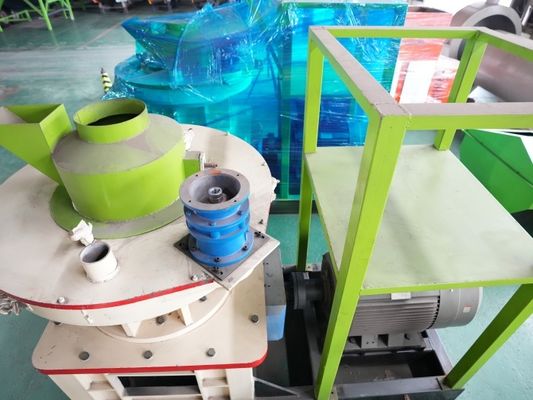

biomass rice husk peanut shell sawdust Alfalfa Fuel Hay Straw Chips Grass wood pellet mill machine

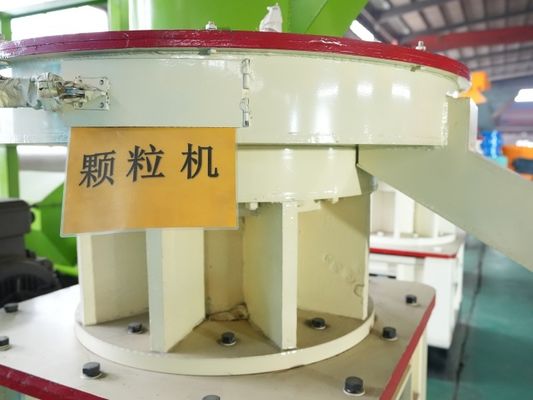

This wood sawdust pellet machine mainly used for making wood pellets , the pellets used for industry, boiler factories , the machine can be produce φ6.0,φ8.0,φ10.0,φ12.0 pellets.

(1)The machine adopt imported SKF or NSK bearings, the motor brand is Siemens or china famous Wannan brand

(2)Driven by gear .more strong than by belt, and the capacity 10% higher than by belt .

(3)the machine also matched the safty equipment , once overload , the safty pin will crack, to protecting the machine lifetime .

Main Features of Wood Pellet Machine

1.Vertical die, unique structure, vertical feeding, is conducive to heat dissipation;

2.Die is static while roller is rotary; materials are evenly distributed because of the centrifugal force produced by rotary rollers;

3.Two sets of lubrication,main shaft and rollers, guarantee the service life, high and stable yield;

4.Air cooling dust removal, long time operation, efficient production, energy saving and environmental protection

5.Double layer die, one machine dual-use, more choice, more harvest.

| Model |

Power

(kw) |

Capacity for

wood pellets(kgs/h) |

Weight of the

machine(kgs) |

Dimension of the

machine (mm) |

| KL-560 |

90+1.5+0.37+1.5 |

1000-1500 |

6100 |

2600x1300x2300 |

| KL-850 |

220+3+0.37(0.55)+2.2 |

2000-3000 |

14500 |

3300x1400x3100 |

| KL-920 |

315+5.5+0.55+1.5+2.2 |

3000-4000 |

18000 |

3800x1680x3400 |

Vertical ring die machine is suitable for pressing all kinds of difficult to bond,hard forming materials ,such as :rice husks,peanut shells,wood sawdust,bamboo powder,corn stalk,grass,coffee shells and so on.Widely used in biomass burning plants,powder plants,wood processing plants,fertilizer factory,chemical factory,food factory ,winery waste reuse,high density molding equipment.

Biomass pellets can be used as raw materials for processing wood chips, straw, rice husks, bark and other biomass and other agricultural and forestry wastes. Through pretreatment and processing, it is solidified into high-density pellet fuel. It is an ideal fuel to replace kerosene. Energy saving and emission reduction have good economic and social benefits. It is an efficient and clean renewable energy.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!