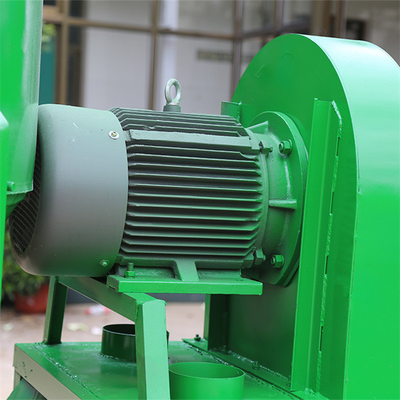

poultry feed mixer electric 220V feed mixing machine animal feed mixer

1. electric animal feed mixer it can also mix wet and dry type feed pellets, corn, peanut shell seeds , rice etc.

2. This feed mixer machine can be with inverter to control its working speed.

3. Animal feed mixer weight is 60kg., height is 870 mm in totally. Diameter is 680mm, bin height is about 500mm.

4. Driven type: power driven

5. Application: to mix grain, corn, seeds etc for feed.

6. Raw materials that it can mix is wheat, corn, rice, soybean, peanut sh, vegetable, seeds, pasticide, animal feed pellets etc.

7. Type: vertical type mixer

8. Mixing method: useing screws to mix raw materials

9. Working capacity: 50-500kg per time

10. Customized or not: yes.

| Model |

Power |

Speed |

Dimension |

Diameter x Height |

weight |

| 50kg |

0.75KW |

35/70 |

80*78*98 cm |

780*420 mm |

80 KG |

| 75kg |

0.75kW |

35/70 |

95*90*98 cm |

900*420 mm |

90 KG |

| 100kg |

1.5KW |

35/70 |

105*100*98 cm |

1000*420 mm |

100 KG |

Rotational speed of reducer shaft and paddle structure can reduce the material weight. As the reduction of gravity, the differences of particle size, specific gravity between materials can be neglected. Intensive stirring movements shorten primary mixing time, and make the mixture faster. Despite the differences in specific gravity and particle size between various materials, the mixer still achieves great performance by fast tossing and dropping of raw materials by mixing blades in interlaced arrangement. (After deceleration of reducer, the rotation speed is 35 rpm, which can be reduced by adding frequency conversion equipment)

The internal barrel surface is smoothed by polishing and equipped with center shaft and double S-shaped paddle. Mixing materials process is fast and homogeneous, which can be finished within 5-10 minutes for each batch. Mixture of special materials need to be confirmed by users.

Main features of feed mixer machine:

1. The raw material can be grain, corn, soybean, wheat, etc., and the special feed can be added into the machine to mix.

2. The feed mixer machine is suitable for the family use and small factories.

3. less area of occupancy, easily to loading and discharging.

4. The feed mixer machine generally used for small feed factory and complete feeding line.

Working principle:

Under the movement of the spiral belt of the mixing shaft, the horizontal mixer causes the inner and outer spiral belts to turn the material in a larger range. The inner spiral belt makes the material move to both sides, and the outer spiral belt moves the material from both sides inward to make the material go back and forth. Blending, the other part of the material is driven by the spiral belt to move along the axial diameter, thus forming a convective circulation. The materials get fast and uniform mixing in a short time.

FAQ

Q1: Are you a manufacturer or a trading company? We are a professional manufacturer with more than 12- years experiences, 31,000sqm workshop and 90 employees. Welcome any spot investigation or real-time video link anytime

Q2: How do you control the products quality? Our machines are authenticated by Ministry of Agriculture and Rural Affairs of PRC. We set independent Quality Control Department to do sample inspection, part inspection, trial running and pre-shipment inspection

Q3:What will be the after-service term? Whole unit guarantee for 12 months after receiving. Free spare parts sending by air or courier within 3 days if any failure caused by quality problem

Q4: Can I get some samples? A: Yes, sample order is available for quality check and market test. But you have to pay the sample cost and express cost.

Q6: What's the lead time? A: Accordingto the order quantity, small order usually need 7-15 days, big order need negotiation.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!