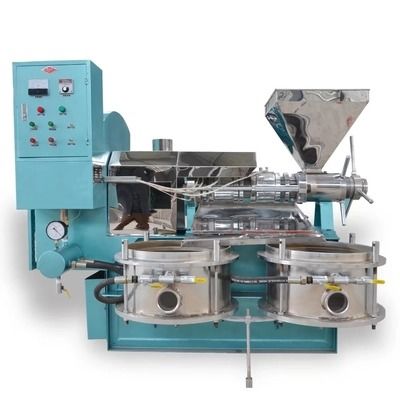

High Quality Oil Making Machine Automatic Oil Press Machine

The high-quality oil making machine, also known as an automatic oil press machine, is a cutting-edge device that revolutionizes the oil extraction process, ensuring superior oil quality and unmatched efficiency. With its advanced features and automated operation, this machine sets a new standard in the oil production industry, delivering exceptional results while optimizing the overall production process.

One of the key advantages of the high-quality oil making machine is its ability to produce oil of superior quality. The machine is engineered to preserve the natural characteristics and nutritional value of the oil, ensuring that the final product retains its flavor, aroma, and nutritional profile. The extraction process involves minimal heat generation, preventing the degradation of delicate compounds such as antioxidants and essential fatty acids. Additionally, the machine incorporates advanced filtration systems to remove impurities and contaminants, resulting in pure and high-quality oil. By prioritizing oil quality, the machine enables producers to meet the increasing demands of consumers who seek premium-grade oils for their culinary and nutritional needs.

Furthermore, the high-quality oil making machine boasts an automatic operation that streamlines the oil extraction process. It eliminates the need for manual intervention and constant supervision, as it is equipped with intelligent controls and sensors that monitor and adjust critical parameters such as temperature, pressure, and extraction time. This automation not only enhances efficiency but also ensures consistent oil production with minimal human error. Operators can set the desired parameters, and the machine will consistently reproduce the ideal conditions for extracting high-quality oil. The automated operation not only saves labor costs but also enables producers to focus on other aspects of their business while the machine efficiently carries out the extraction process.

Moreover, the high-quality oil making machine excels in its production capacity and efficiency. It is designed to handle a large volume of raw materials, allowing for high-speed oil extraction within a shorter timeframe. This increased production capacity is particularly beneficial for commercial-scale operations, as it enables them to meet market demands effectively. The machine's efficient design optimizes the extraction process, maximizing oil yields while minimizing waste. This results in improved overall efficiency, reducing resource consumption and production costs. By optimizing the production capacity and efficiency, the machine empowers producers to scale their operations and meet the growing demands of the market.

Additionally, the high-quality oil making machine is designed for user convenience and ease of operation. It incorporates user-friendly interfaces, touch screens, and programmable settings that allow operators to customize the extraction process according to their specific requirements. The intuitive controls and interfaces make the machine easy to operate, reducing the learning curve and training time. Safety features and automatic shut-off mechanisms ensure operator well-being and prevent accidents, further enhancing the machine's user-friendliness and reliability.

Furthermore, the high-quality oil making machine is often engineered with energy efficiency in mind. It incorporates energy-saving components and optimized mechanisms that minimize power consumption without compromising performance. This energy-efficient design not only reduces operational costs but also aligns with sustainability goals and environmental considerations. By choosing an energy-efficient machine, producers can contribute to a greener and more sustainable production process.

When selecting a high-quality oil making machine, it is essential to partner with a reputable manufacturer or supplier. Look for companies with a proven track record in producing reliable and efficient oil extraction equipment. Consider factors such as production capacity, compatibility with various raw materials, ease of maintenance, and after-sales support to ensure a seamless integration of the machine into your production operations.

In conclusion, the high-quality oil making machine, or automatic oil press machine, sets new standards in the oil production industry. Its ability to produce superior quality oil, automated operation, high production capacity, user-friendly design, and energy efficiency make it an invaluable asset for oil producers. By utilizing a high-quality oil making machine, producers can optimize their production processes, deliver premium-grade oils, and meet the increasing demands of consumers in the industry.

Product Paramenters

| Model |

6YL-60 |

6YL-70 |

6YL-80 |

6YL-100 |

6YL-125 |

6YL-150 |

| Power |

Power |

2.2 kw |

3kw |

5.5 kw |

7.5 kw |

15kw |

22kw |

| Pump |

0.55 kw |

0.75 kw |

1.1kw |

1.1kw |

1.5kw |

2.5kw |

| Heater |

0.9 KW |

1.8kw |

2KW |

2.2kw |

2.8kw |

4.5kw |

| Capacity(kg/h) |

30-60 |

50-80 |

80-130 |

140-280 |

350-400 |

350-450 |

| Weight |

220kg |

280kg |

780kg |

1100kg |

1500kg |

1500kg |

| Dimension(m) |

1.2*0.78*1.1 |

1.4*0.86*1.26 |

1.7*1.2*1.5 |

1.8*1.3*1.68 |

2.1*1.4*1.7 |

2.5*1.75*2 |

Our Services

Pre-Sales:

1. Select suitable equipment model.

2. Design and manufacture products according to clients special requirements.

3. Train technical personnel for clients.

4. Professional suggestion for customer.

Sales of services:

1. Take photos(including raw material,semi-products,final products and loading products).

2. Pre-check and accept products ahead of delivery.

3. Prepare all clearance documents,so that the customer clearance smoothly.

After-sales service: ,

1. Provide civil engineering drawings of the equipment.

2. Free training(including installation, maintaince) to every customer.

3. Install and debug the equipment,ensure the machine running smoothly.

4. Examine the equipment regularly.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!