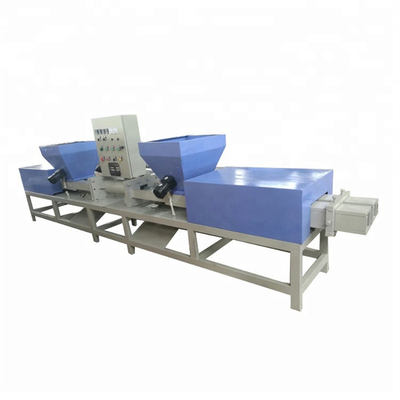

Hot Press Charcoal Briquette Machine Wood Block Machine Brick Production Line Automatic Manufacturing Plant

The wood block making machine is a recycling machine by using the Hot Pressing Principle to process wood shavings and wood sawdust raw materials into wood pallet foot blocks which is widely used in transportation.

The wood block press machine produced by our plant mainly use shaving, sawdust and other waste materials to produce wood shaving pier or block. Through the drying, mixing glue sizing and heating process,the pier is smooth,waterproof and strong enough to bear the force for nails.we can make the mold according to the size and specifications required by customers.The finished product is fumigation-free and inspection-free.

The specification of wood sawdust block press machine

The machine could make different size wood block as per your request, such as:

75*75,80*100,80*120,90*90,90*140,100*100,100*115,100*140,140*140 ,145*145, etc.

technical data of wood block machine

| Model |

MK-2 |

MK-4 |

MK-6 |

| Header Qty |

Double Headers |

Four Headers |

Six headers |

| Size |

4800*760*1300 |

4900*800*1800 |

4900*940*1800 |

| Capacity |

2-3m3/24h |

4-5m3/24h |

6-8m3/24h |

| Glue water amount |

80-100kg/m3 |

90-110kg/m3 |

100-120kg/m3 |

| Density |

550-600kg/m3 |

550-600kg/m3 |

550-600kg/m3 |

| Weight |

1000kg |

1500kg |

2200Kg |

| Power |

12 kw |

12-15 kw |

24kw |

1.Raw Materials

wood shavings,sawdust and the other wood waste material.

2.The production line

The production line is made up of the crusher, dryer, the gluing machine, hot pressing machine and Saw to cut the block piece by piece.

3.Features of the finished products

The feet pier or sawdust block with the advantage of flat, smooth and artistic surface, good waterproof(it should not disintegrate after 48 hours in the water,and wind, sun) the nail force strong.you can made according to customer specifications and requirements,export inspection exemption fumigation free, formaldehyde release a quantity (E2) The products conform to the national standard, which combined strength of 1.07 mpa, grasps the screws force vertical for 1590 N, parallel for 1660 N which is the ideal material for fumigation-free wood tray holder (feet pier, a leg). The Fumigation-free, non-heat treatment product is mainly used in place of the foot pier in the pallets logs.

Equipment disposition: Generally four hot pressing are a production line, must provide the dryer, the gluing machine, grinder each. (dryer, gluing machine, crusher and so on supporting facility customer buys in addition.

Personnel disposition: Production personnel 4-5 person per shift. And raw material sort (screening), drying, spreads 2-3 people,looked that machine 2 people (a person may look at two machines.

Production cycle: After confirmation order form and payment advanced payment, 40 super craftsmen ship factory delivery. Our factory is responsible for the technical training, and provides the consummation the post-sale service.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!