1. The Fish Feed Pellet Making Machine has the function of heating and puffing, it is mainly used for producing fish feed ,also it can be used for making dog,cat or other pets feed .

2. The machine can produce different particle shapes, and we will offer 6 moulds for free, you can choose the shape you like.

3. Raw materials like soybean meal, rapeseed, rice bran, fish meal, bone meal, corn meal, flour and so on, so the feed pellet processed by the machine has rich nutrition.

4. This machine is very popular in the country of Peru, Ghana, Belgium, Niger, Angola, Malaysia etc.

5. We have a lot of Models according to its capacity, you can choose one as your need.

| Model |

Main power

(KW)

|

Feeding power

(KW)

|

Cutter power

(KW)

|

Spiral diameter

(mm)

|

Productivity

(t/h)

|

Size

(mm)

|

Weight

(kg)

|

| DGP40 |

4.0 |

0.4 |

0.4 |

40 |

0.03-0.04 |

1400x1030x1200 |

240 |

| DGP50 |

11 |

0.4 |

0.4 |

50 |

0.06-0.08 |

1400x1030x1200 |

320 |

| DGP60 |

15 |

0.4 |

0.4 |

60 |

0.12-0.15 |

1450x950x1430 |

480 |

| DGP70 |

18.5 |

0.4 |

0.4 |

70 |

0.18-0.25 |

1600x1400x1450 |

600 |

| DGP80 |

22/27 |

0.4 |

0.75 |

80 |

0.3-0.35 |

1850x1470x1500 |

800 |

| DGP90 |

30/37 |

1.1 |

1.5 |

90 |

0.4-0.45 |

1900x1500x1600 |

1200 |

| DGP100 |

37 |

1.1 |

1.5 |

100 |

0.45-50 |

2000x1600x1600 |

1500 |

Electric start diesel engine: For areas with insufficient power, diesel engines can solve power problems and are easy to use.

Control cabinet: button operation, easy to understand, and master

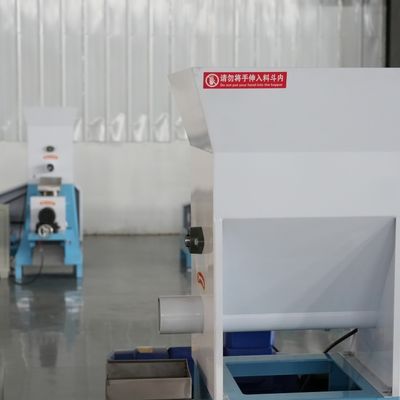

Upper Feeder: The feeder is of an automatic speed control type, consisting of a hopper, a pusher screw, and an outlet tube.

Pour the mixed raw materials into the feed bin. All-round 360-degree circular stirring. screw pushing into the raw materials, automatic uniform feeding.

Sleeve type extrusion screw device: The extrusion screw is a sleeve type combined structure. The material is pushed from the feed box to the compression chamber from the extrusion screw and is continuously heated by different degrees of extrusion until it is discharged.

Molds: Different feed pellet shapes by changing different molds.

Rotary cutting device: rotary cutting device of variable frequency speed regulation, which can adjust the rotating speed of the blade arbitrarily to control the cutting speed and length.

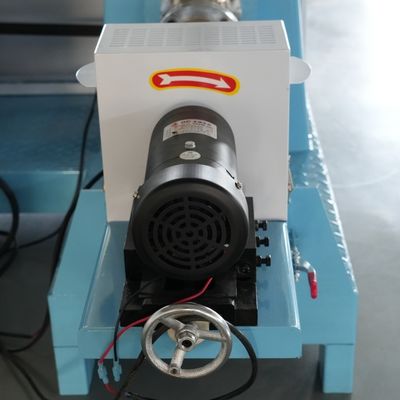

Motor: The motor controls the feeding and cutting speed.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!